Joint Liner Interaction

1.0 Introduction

This tutorial demonstrates how to model liner support in a jointed rock mass, when joints intersect excavation boundaries on which liner support will be installed. To correctly model the interaction of the joint-liner intersections, we must define a Composite Liner which includes a joint at the liner-rock interface.

In this case, the liner will resist slip on the joints such that it remains intact and continuous around the excavation.

The analysis will be conducted in two parts. The first part shows the response of a tunnel in jointed rock without a liner. The second part shows the effect of adding the liner support.

2.0 Compute: Unsupported Model

The unsupported model has the excavation boundary defined, joints added, mesh, and field stress defined. There is no liner.

2.1 Compute: Without Support

- Select: File > Recent Folders > Tutorial Folder

- Open the file Joint-Liner Interaction Part 1

- Select: Analysis > Compute

3.0 Results and Discussion: Unsupported Model

- Select: Analysis > Interpret

The maximum compressive stress for Stage 1 will be displayed.

As expected, the stress generally increases with depth. There are some discontinuities in stress across the joints, however, the variations in observed stress are small.

- Select: Stage 2 tab.

- Low stresses are visible around the tunnel with higher stresses further out.

- This suggests that the rock around the tunnel has failed and cannot support high stresses.

Confirm this by plotting the failed elements

- Turn on the display of yielded elements

- Turn on the display of yielded joints

The model should appear as follows:

There is extensive failure around the tunnel that extends a significant distance into the rock mass, and most of the joints close to the tunnel have failed. This is also shown during computation where model convergence could not be achieved within the set maximum number of iterations. A summary of model convergence can be found in the engine log file which can be accessed in the Interpreter by going to Analysis > Log File.

- Now, plot the deformation by changing the contours to Total Displacement

- Select: Display Deformed Boundaries

- Turn off Yielded Elements and select Zoom Excavation

The model will appear as shown.

The tunnel has been squeezed under stress and its shape has changed to become more elliptical. The joints are also showing some slip, as can be observed from the offset between opposite sides of each joint where each joint intersects the tunnel boundary.

Examine the slip on the joints by plotting the shear displacement.

- Right-click on the joint that intersects the top of the tunnel.

- Select Graph Joint Data.

- For the Vertical Axis, select Shear Displacement and click Plot.

The graph will appear like below:

This plot shows almost 10 cm of slip on the joint near the tunnel surface.

The next section of the tutorial will analyze the effect of adding support (a shotcrete liner) on deformation and failure in the tunnel.

4.0 Adding Support (Composite Liner)

Go back to the RS2 Modeler. Open the saved file from the previous part of this tutorial if necessary.

4.1 Modeling Joint-Liner Interaction

The excavation is intersected by rock joints and requires liner support to prevent collapse. To correctly model the interaction of the joint-liner intersections, a Composite Liner must be defined. This liner includes a joint at the liner-rock interface. This correctly models the shear force which is applied to the liner by the differential slip of the joint endpoints at the joint-tunnel intersections.

4.2 Composite Liner Properties

For this example, it will be sufficient to define a Composite Liner which is composed of a single liner and a joint.

First, let’s specify the properties of the single liner.

- Select: Properties > Define Liners

- Change the Name of Liner 1 to Shotcrete and leave all other values as the default. The dialog should look like this:

- Click OK to close the dialog.

Now, define the properties of the joint between the liner and the rock.

- Select: Properties > Define Joints

- Click on the tab for Joint 2. Change the Name to Liner Joint.

- Uncheck Groundwater Pore Pressure and Additional Pressure under Additional Pressure Inside Joint.

- Leave all other selections as default values as shown.

- Click OK to close the dialog.

Now, set up the composite liner, which will be composed of the shotcrete layer and a joint.

- Select: Properties > Define Composite

- The Number of Layers box should be set to 1.

- Set the Liner Type pull-down menu to Shotcrete.

- Ensure the Joint Interface check box is active and the Joint pull-down menu is set to Liner Joints. The dialog should look like this:

- Click OK to close the dialog.

4.3 Add Support

![]()

- Select the Stage 2 tab; the liner will be applied in this stage.

- Select: Support > Add Liner

- In the Add Liner dialog:

- Make sure the Composite Liner check box is selected.

- The Liner Property should be Composite 1.

- The value for Install at stage should be 2, as shown.

- Click OK to close the dialog.

- Now select all the segments that make up the tunnel by clicking and dragging a selection window (hold down the left mouse button and drag a window to encompass the entire tunnel).

- Hit Enter to finish selection.

The model should look like this for Stage 2:

The model is now complete with support. Save the model before proceeding to compute.

5.0 Compute: Supported Model

- Select: Analysis > Compute

6.0 Results and Discussion: Supported Model

- Select: Analysis > Interpret

The maximum compressive stress for Stage 1 will be displayed. The model behaviour for Stage 1 will be the same as before.

- Select: Stage 2 tab.

A ring of high stress is visible around the tunnel, yet slightly distanced from the tunnel boundary. This suggests that the rock directly adjacent to the boundary has failed and cannot support high stresses.

Confirm this by plotting the failed elements.

- Turn on the display of yielded elements

- Turn on the display of yielded joints

The model should appear as follows.

Elements around the tunnel have failed in shear and joints near the top and bottom of the tunnel have failed (shown as red lines). However, the failure of elements and joints is much less severe than observed in the unsupported model. Note that none of the liner elements can fail because the liner material type was set as elastic.

- Now, plot the deformation by changing the contours to Total Displacement.

- Select: Display Deformed Boundaries

- Turn off Yielded Elements and Yielded Joints, then select Zoom Excavation

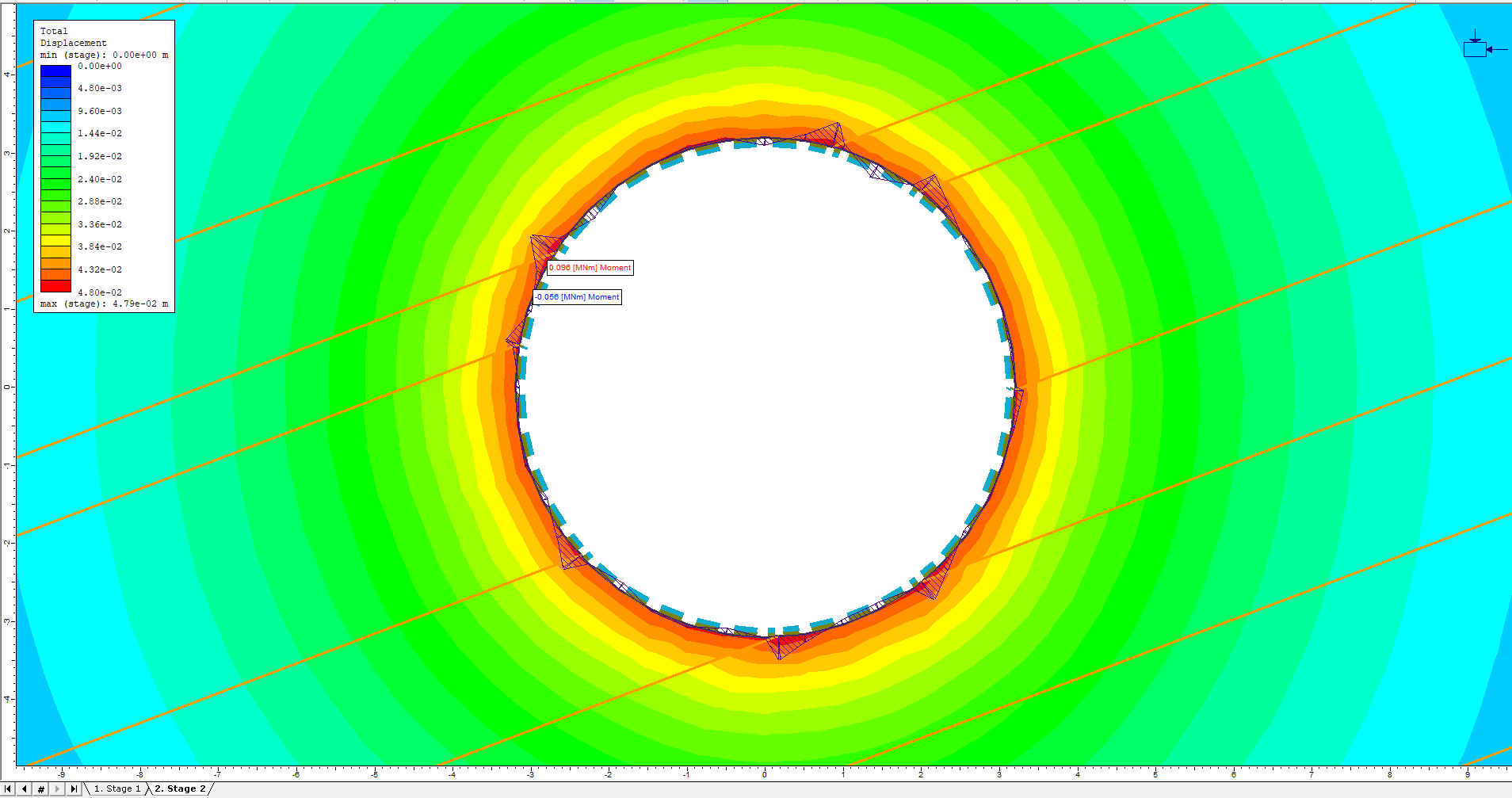

The model will appear as shown.

The tunnel (and liner) have displaced inwards and there is little slip on the joints compared with the amount of tunnel closure. The tunnel has also maintained its circular shape.

The amount of slip on the joints is small but it is not zero. Let’s examine the slip on the joints by plotting the displacement.

- Right-click on the joint that intersects the top of the tunnel.

- Select: Graph Joint Data.

- For the Vertical Axis, select Shear Displacement and click Plot.

The graph will appear as shown below.

The amount of slip is increasing as the joint approaches the tunnel, however, the slip on the joint is about 50 times less than the slip observed in the unsupported tunnel.

Now examine the behaviour of the liner.

- Go back to the window showing the tunnel in Stage 2.

- Turn off the deformed boundaries display.

- Right-click on the liner and select Show Values > Bending Moment. The screen should appear as follows:

There are very large bending moments where the liner is intersected by the rock joints. The joints are trying to slip but they are being resisted by the liner, which undergoes shear deformation causing the largely observed bending moments. The liner is responsible for maintaining the integrity of the tunnel.

7.0 Additional Exercises

Repeat the previous analysis, but instead of applying a Composite Liner with a joint, apply a regular (single layer) liner. Running the analysis will show the difference in the liner behaviour.

The following figure shows that the liner bending moment results are completely different from the Composite Liner (with joint) bending moments.

The above image shows the liner bending moment for a single layer liner with no joint between liner and rock.

At the tunnel / joint intersections, the liner bending moments decrease to minimum values, rather than maximum values. This is because the liner is effectively discontinuous at these locations and does not resist differential movement of opposite sides of each joint.

The reason that the Composite Liner (with joint) gives such different results from a single layer liner (with no joint) is primarily due to the way in which RS2 assigns node numbering at the intersections of joints. When a joint is present between the liner and the rock, this correctly models the physical interaction of the joints, tunnel boundary, and liner. As a result, the model using a single layer liner with no joint between liner and rock could not achieve convergence within the set maximum number of iterations due to the discontinuous liner behaviour which could not generate adequate support. A summary of model convergence can be found in the engine log file which can be accessed in the Interpreter by going to Analysis > Log File.

Finally, the following figure illustrates the deformations for all three cases (unsupported, single liner, composite liner). Note: the scale factors used to display the deformed boundaries are as follows: unsupported (Scale Factor = 1), single liner (Scale Factor = 1), composite liner (Scale Factor = 20).

The overall deformation for the single liner is not much different from the unsupported case. The differential movement at the joint ends is more pronounced for the single liner compared to the unsupported case. For the composite liner, the overall deformations are about 20 times less than the unsupported case (note scale factors), and the deformation pattern is relatively uniform and circular.

Deformed boundaries for (left to right) – unsupported, single liner, composite liner. Scale factor for deformations = 1, 1, 20, respectively.

This concludes the Joint-Liner Interaction Tutorial.